Level control

Features

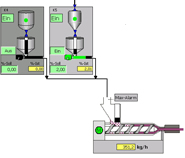

Continuous blending with level control is a method to feed material under free fall conditions into a fully filled extruder. Because the continuous blending in free fall has no response of the total throughput needed, a level indicator is positioned on the extruder inlet. The signal controls whether the level is rising or decreasing. According to that information the throughput set-point of the blender is changed to deliver more or less material.

The advantages of this process is:

- Ideal mixing of all components in free fall

- No separation of components in case of a minimal storage in front of the extruder

- Very useful if small amounts of material have to be added as powder for foaming agent, additives or masterbatch

Level indication

Features

The level on the extruder can be determined by different measures as:

- Capacitive gauges, dunking into the feeded material

- Ultrasonic gauges, sampling the surface of material inlet

- Weigh hopper, measuring the weight of the inlet material

The processed material, in mounting conditions and the price of the additional equipment decides about suitaiblity and adoption.