Throughput control on regrind extruder

Features

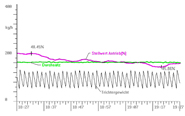

In blow moulding regrind of all cuts is recycled in-line. Even if this material is mixed with virgin material differences in temperature, bulk density and shape of regrind becomes obvious in changes of throughput in a range of 5 ... 10% as shown on the left side.

Because of that influences throughput control is recommended not only for continuous extrusion but also to fill an accumulator head of a cyclic machine reproductively. All changes in filling the accumulator can be reduced down to 1... 2% of filling level in respect to cycle time. This measures are paid back by a reduction of scrap.

Co-ex machine for blow moulding

Features

Continuous blow moulding is the domain of producing parts with more than 5 kg and for fuel tanks and drums designed in multi-layer technology.

The shape of a parison depends from a few parameters as throughput, clearance within the die and melt viscosity. Accordingly, all of these have an influence on part weight, too.

Gravimetric control on all extruders results in constant layer distribution and a variation of throughput in a range of 1%. Consequently the variation of part weight can be reduced to about 2% or better.