Material savings

In which time is the additional investment amortised?

For the most extruded products minimum dimensions or weight per meter length have to be guarantied. A large positive tolerance results in high additional cost on material.

Gravimetric metering and blending determines the excess of material and improves the yield by control.

By calculating the ROI - Return on investment - the profitability of gravimetric control can be evaluated.

What helps in improving quality?

Throughput Measuring and controlling reduce deviations resulting from material and feeding tolerances by factor 5...10 compared to non-controlled metering systems. In particular the process capability is improved for processing regrind,for material with changing viscosity and for material with variations in bulk density.

On control not only tolerances are reduced but also bias is diminished.

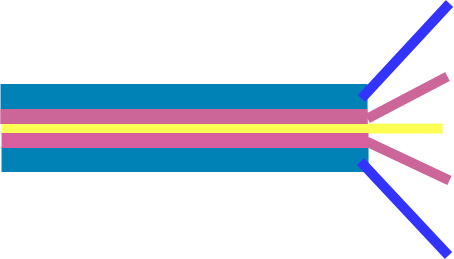

A proper layer distribution achieved by gravimetric is an essential in co-extrusion.

Measurement of hidden layers

How to measure layer thickness of an inner layer?

In co-extrusion the average thickness of a single layer is derived from throughput and line speed. On many production lines it is the only chance to measure the thickness of an inner layer.

The accuracy and resolution of gravimetric measurement is much better than this of a comparable optical gauges like light-section. Especially in measuring thickness in a range of µm the performance of the gravimetric technology is obviously better.